In general, a bathroom floor should be waterproofed before tiling. And when it comes to the shower floor, waterproofing goes without saying. Using a waterproof membrane and sealing the joints of the waterproof membrane are some of the ideal ways to protect the substrate from water and moisture. Also, it is imperative to seal the corners near the bath and shower.

Let’s delve deeper into the waterproofing a shower floor procedure before tiling.

Shower pan liners

The purpose of a shower pan is to hold the water that goes through the grout and cement. Install a mortar bed over the subfloor sloped to weep holes in the drain. As the mortar bed is sloped towards the drain, the tiles should then be installed.

A mortar bed provides load distribution and a bonding surface for the tile. Put a waterproofing membrane called pan liners over this slope and clamped it into the drain. Pan liners consist of copper, lead, polyvinyl chloride, or chlorinated polyethylene.

Hot mop shower pans

The hot mop is another method of waterproofing the shower floor before tiling. This process uses mortar mix cement, asphalt, fiberglass mesh, and roofing felt to build up pan liner. Layers of tar paper are adhered to cover the surface using hot asphalt. Once the hot mop process is complete, then the mud of the tile set is prepared to install tiles using thin-set mortar.

Liquid membranes

Liquid membrane waterproofing products require multiple coatings along with a good drying time. The process requires no primers and seams to treat and transition through walls and corners.

Just like a paint application, liquid membranes are rolled, brushed, and sprayed onto the substrate. However, you need to apply several coats to avoid voids or pinholes that allow water penetration to the substrate.

Using a liquid membrane is the easiest and cheapest waterproofing method. It can be applied to any surfaces that come into contact with water or moisture. This is used in shower floors and bathroom walls. As shower floors are susceptible to leakage, ensure these surfaces have slight pitches to the drains in addition to applying liquid membrane waterproofing.

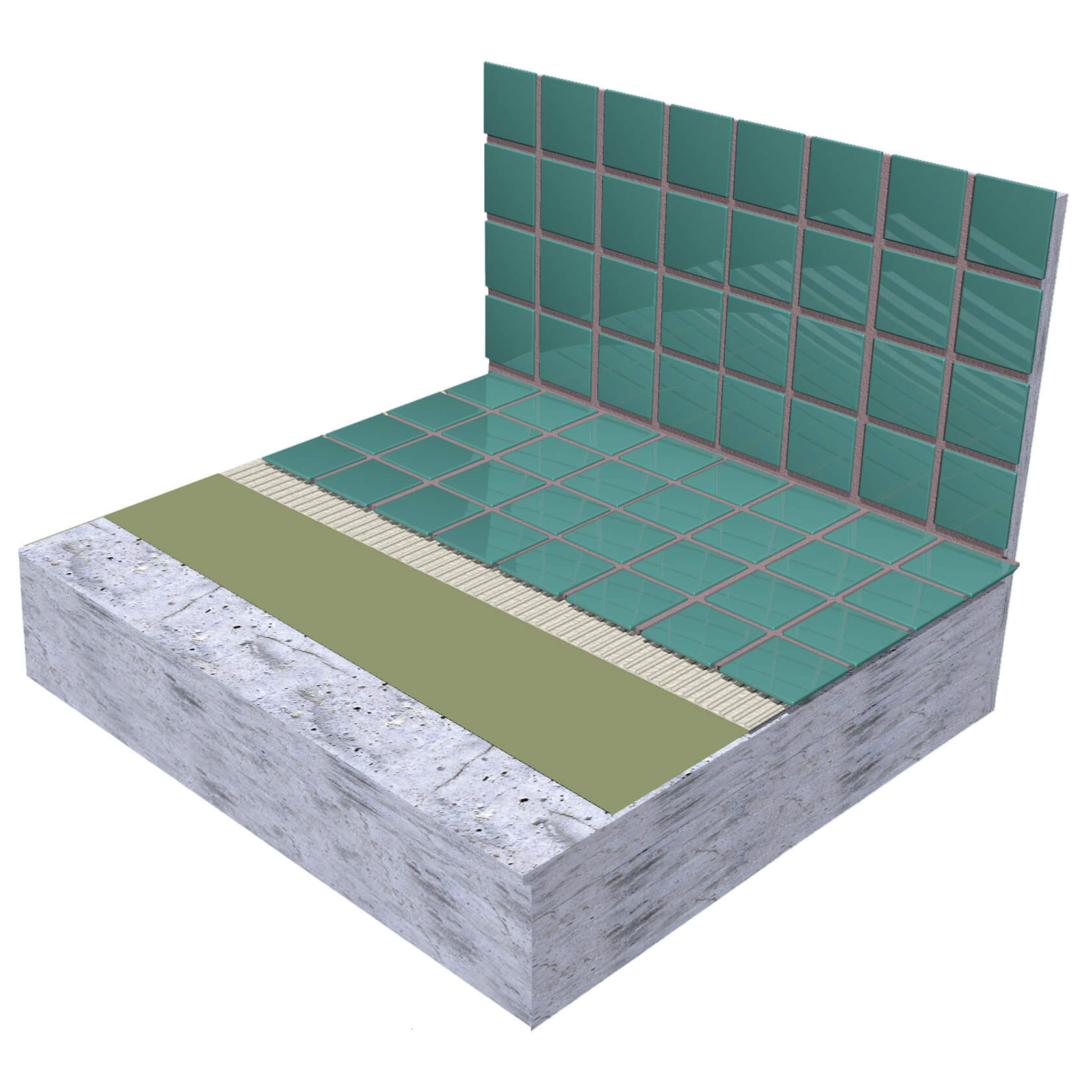

Sheet membranes

In the sheet membrane, the substrate is bonded to the waterproofing system with either adhesive or a thin-set mortar. Usually, sheet membranes like elastomeric or plastic are used to bond to the substrate before installing tiles on the shower floor.

Due to their pliable nature, sheet membranes are easy to roll out onto the shower floor or any part of a wet room. Some sheet membranes can also act as an acoustic barrier as they provide soundproofing.

Foam shower bases

Foam shower bases come in a kit that contains different components for the shower pan. These include membrane bonding shower drain, foam shower curb, corners, and seam tape. Foam shower bases are in standard sizes and designed for either right or left-hand drain orientation. Most importantly, these foam materials are trimmed to match any shower floor size and position of drains only by using a simple hand tool like a utility knife.

It is simple to install a foam shower base to the subfloor by using thin-set tile mortar. However, you must seal the seams with special membrane corner pieces or strips of fiberglass tape. You have to cover it with waterproof adhesives.

Kerdi waterproofing

Kerdi is a hydrophobic polymer fabric. It adheres to any surface – concrete, cement, backer board, drywall, or wood shower floor. kerdi is designed to bond with thinset. Therefore, you can install the tile directly on top of the kerdi fabric. Since kerdi fabric is actively hydrophobic, overlapping kerdi seams create a completely waterproof seal.

RedGuard waterproofing

RedGuard is just another name for paint-on waterproofing material. It bonds well with concrete, cement backboard, drywall, and plywood. This is typically a rubbery paint that dries to form a plastic-like waterproof barrier. Paint-on waterproofing is technically code-approved to use for waterproofing shower floors before tiling.

Using any waterproofing materials for the shower floor gives peace of mind with great results.

Some helpful tips

While some membranes have a sticky back and can be directly attached to the surface, others need some adhesive material to bond them to the surface. Waterproof sealing tape is required to seal the joints of the waterproof membrane.

Why shower floor waterproofing is imperative before installing tiles?

Moisture is the greatest threat to a bathroom caused by leaks, improper shower and bathtub area waterproofing, and inadequate ventilation. Below are some of the impacts allowing moisture or leaks inside your bathroom.

Waterproofing the shower floor before tiling is a significant part of your bathroom. Hopefully, this article on how to waterproof a shower floor before tiling is helpful enough to guide you in your shower floor waterproofing plan.

Welcome to Tile Pro Depot! We established this site to service the specific needs of the tile installation professional. Tile installation tools, tile setting materials, premixed grout and more tile installation products online at Tile Pro Depot.