The quality and finish of tile installation largely depend on the type of subfloor. Subfloors, whether concrete or wood, needs some work to make them ready for tile installation. The subfloor surface must be flat and level without undulations and meet the industry standards according to ANSI specification A108.02-4.1.4.3.1 about subfloor surfaces.

The specification has tight tolerances, and installers must fix the floor so that it is flat enough to lay the tiles perfectly. Since ceramic and porcelain tiles are strong but delicate, their durability depends mostly on proper installation against a prepared level surface. The problem is that subfloors are never of the desired quality to ensure satisfactory tile installation.

Installers must use some underlayment to make good of the imperfections of subfloors and ensure adherence to the best practices in tile installation. For installing ceramic floor tiles, here are four types of underlayment structures.

Cement-based backer board

Cement-backer boards consist of a layer of a mixture of cement-like material and fiberglass mesh that creates a strong bond. The sheets are available in varied thicknesses of ½-inch and ¼-inch and sizes 3’x5′ and 4’x8′. The sheets being heavy, smaller sizes are easy to handle, especially for DIY enthusiasts.

Cement-based backer boards pasted on the floor with thin-set adhesives was a revolutionary discovery in the ceramic tile business as it allowed anyone to lay a structurally solid base for tile installation. Since its introduction in the 1970s, cement-based backer boards made tile installation quicker and cheaper.

Cement-based backer board products are suitable for interior and exterior applications.

Concrete slab

A concrete slab can serve as the best underlayment for ceramic tiles as it closely resembles the solid mortar bases once the mainstay of tile installation. However, the concrete slab should be perfectly flat and level besides having high stability without any possibilities of heaving or settling. However, when installing tiles on a concrete slab, you must not cover the expansion joint of the slab to prevent the tiles from cracking. To prevent tiles from cracking, the norm is to use an uncoupling membrane as an intervening material that creates a gap between the concrete slab and the tiles.

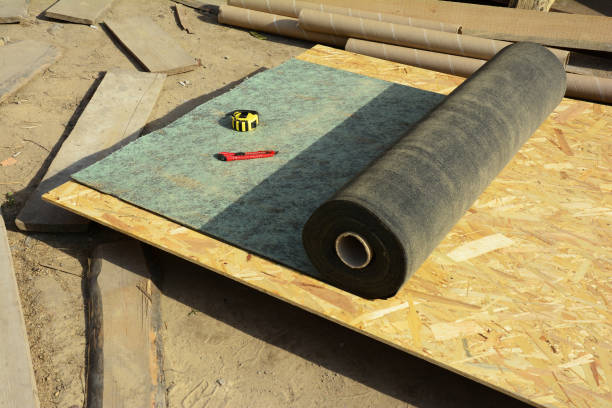

Exterior grade plywood

Exterior grade plywood is another underlayment for tile installation. Since the bonding adhesives of exterior plywood are waterproof, water seepage through the tile surface does not affect the underlayment. With no chances of wood-swelling, the underlayment remains intact and supports the tile surface perfectly over the years. Usually, exterior grade underlayment is ideal for plywood subfloor or OSB to create a two-layer base. When using exterior plywood underlayment, it is significant to avoid overlap of seams between the layers, and screws attaching the two layers of plywood should never reach the floor joists.

Mortar bed

Mortar bed underlayment involves creating a mortar bed by pouring a thin layer of cement mortar on the subfloor and placing the ceramic tiles on it to ensure that these stay embedded within the mortar. Wire-mesh reinforcement is used to strengthen the mortar. Laying mortar is advantageous because the installer can accommodate minor unevenness and flaws in the subfloor. However, mortar bed underlayment is expensive because it involves skilled labor and takes considerable time to achieve the desired level of surface finish for proper installation of the tiles. Although tiles having mortar bed underlayment look elegant, it is not a popular choice today because of the rarity of highly skilled workmen who can do a good job, the long time it takes to complete the work, and the high costs.

Cement-based backer boards and concrete slabs are more viable options for underlayment for tile installation, hence the most popular.